The product is a polyester two-dimensional, three-dimensional silicone finishing agent crimped fiber, the use of special materials polymerized to a variety of ultra-high molecular polymer compound effective surfactants can be given a special fiber silky feel, and have good elasticity.

1, Uses

1) Effective Ingredients: 38%

2) Features and Benefits:

(1) forming a reticular chemistry of a surface coating of good fiber

(2) an excellent soft, smooth, fluffy feel, fully resilient reinforcing fibers

(3) having a high permeability, it can enter the interior of the fibers so that the fibers become soft, smooth, fluffy

(4) green-aids, free of APEO, NPEO, in line with European ROHS environmental standards

3) the ratio applicable

A:B:AJ-3:AJ-2 = 7:2:1:0.35

2, Performance characteristic table

|

Name |

A |

B |

AJ-3 |

AJ-2 |

|

Appearance |

White emulsion |

White emulsion |

colorless transparent liquid |

colorless transparent liquid |

|

Assay |

38% ± 2 |

38% ± 2 |

12% ± 2 |

≥96% |

|

Ph value |

9-10 |

7-8 |

4-5 |

7 |

3. The method of preparation:

1) two-dimensional method of bath ingredients

(1) Padding bath tank (as 103.5kg Silicone oil dope, 1000kg water, for example):

After (a) Silicone oil in a clean bucket, the AJ-2 added to 30kg feed 3.5 kg of water, stirred for 10 minutes into the half put away in advance of padding bath water tank

(B) A material 70 kg, B material 20 kg with bath tank, stir

(C) the remaining water was added to the bath, add 10 kg AJ-3 material Stir to use padding

(2) spray formulation bath method (with a three-dimensional manner bath ingredients)

(3) additional liquid ingredients manner (as 10.35kg Silicone oil liquid, 50kg water, for example)

(A) feeding the AJ-2 30kg of water was added 0.35 kg, stirring for 10 minutes

(B) A material 7 kg, B 2 kg with the material with oil bath, stirring for 10 minutes

(C) the remaining 20 kg of water was added with sump Stir, add 1 kg feed AJ-3 was stirred for 5 additional minutes to use

2) a three-dimensional manner bath ingredients (as 10.35kg Silicone oil dope, 100kg water, for example)

(1) The AJ-2 30kg feed 0.35 kg of water was added, stirred for 10 minutes

(2) A material 7 kg, B 2 kg feed with bathing tank, stirred for 10 minutes

(3) The remaining 70 kg water was added to the bath stirring well, add 1 kg feed AJ-3 was stirred for 5 minutes using a spray

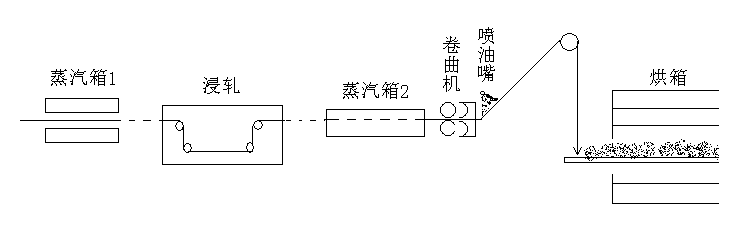

4, Post-weaving Silicone oil fueling conditions:

1) the location and method of supply

D Best Fuel method:

Padding: will "padding bath tank dosing method" with a good bath directly at a certain time (according to the wire handle the situation and requirements), supplemented by "additional liquid dosing method" with a good bath.

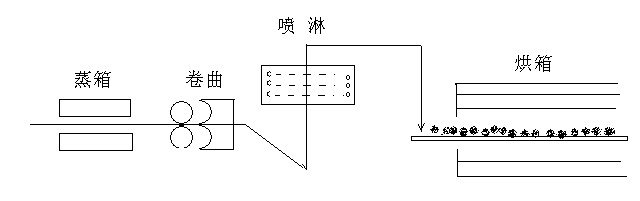

Spray: Spray directly after crimping machine according to "three-dimensional manner ingredients bath" with a good bath.

D Best Fuel method:

Spray: Spray directly after crimping machine according to "three-dimensional manner ingredients bath" with a good bath.

2) oven temperature:

[A] preheating zone area: 140 ℃

[II] drying zone: 170 ~ 190 ℃, the highest not be greater than 210 ℃

District cooling zone [three]: 140 ℃

3) optimum fiber oiling rate of 0.3% to 0.4% by weight, per ton of fiber used Silicone oil 8kg ~ 10kg.

5, Cautions

1) This product has good compatibility with cationic and non - ionic , can not be used with anionic.

2) The product should be stored in clean, sealed plastic or steel drum, shelf life is six months.